Dairy Case Study

The scheme at Ides Barn has given John state-of -the-art facilities, better surroundings for his animals, and has allowed him to expand his herd and make the business more efficient.

“At a time when dairy farming is under pressure, it’s more important than ever to have up to date facilities, the right equipment and a herd that’s big enough to cover the fixed costs” he explained.

Up until November 2008, John had none of those things. The third generation of a dairy farming family, he was operating from Manor Farm, East Dean, a traditional flint and brick dairy a mile or so up the road from the Ides Barn site.

The buildings were old and unsuitable, the equipment was becoming outdated and the herd limited to 130. The loose yard set up meant dealing with mastitis was an ongoing problem and making a living from milk was becoming more difficult.

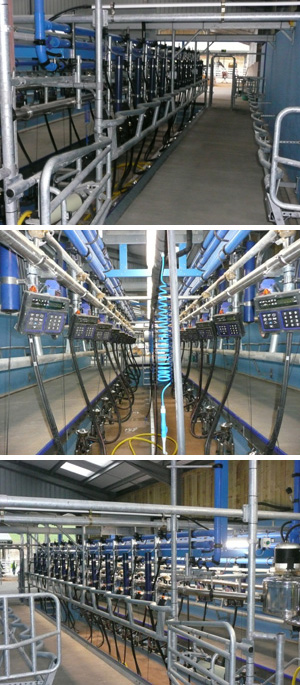

The scheme includes covered accommodation for 200 cows, a new general purpose building, two covered silage barns, a new 24 unit parlour and a covered collecting yard and handling facilities.

It’s all a far cry from Manor Farm, where the Holt family business had been based since the 1960s

A delighted John Holt is now in the process of building up his herd of Holstein Friesians with the aim of reaching what he sees as a cost effective 200 animals by the end of this year.

“The new facilities are a massive improvement on what we had before. Everything is purpose built and works properly, first time every time. The move from loose yards to cubicles has made keeping the animals in peak condition much easier and the computerised kit makes the whole milking process simple and controllable” he said.

John is optimistic about the long-term future for the dairy industry and sees increasing demand for milk. He has a contract to supply Tesco via Arla and believes that if the price remains stable the future looks bright for farmers who are operating efficiently.

The DeLaval parlour at Ides Barn features sophisticated herd management software that not only monitors yield for each cow but can help spot health problems, divert the milk into a dump line if necessary and then divert the animal to a holding pen for treatment.

Goodrowes installed the equipment, which includes a fully automated plant washer that is activated by the push of a button. The man who will be pushing the button, herd’s manager Iain Todd, is impressed by the new equipment.

The cows too have comfortable, spacious surroundings and are bedded on sand which helps keep diseases at bay.

The internal walls of the dairy have a fibreglass surface that means they can be hosed down effectively in order to maintain the highest standards of cleanliness.

Goodrowes also utilised the use of their Case Maxi Sneaker trenching machine to install 1300 metres of 90mm MDPE water pipe from the Portsmouth Water Company water main in Droke Lane across fields and into the new site at Ides barn.

Connections across the field and to various points at Ides Barn were fusion welded by Goodrowes to guarantee a leak free perfect connection for many years to come.

Overall the end project was finished to an extremely high standard, fit for 21st century dairying and created a pleasant environment for live stock and stockman alike.

Published by South East Farmer in april 2009 written by Malcolm Triggs